Construction Starts Post Solid Gain in August

Total construction starts rose 19% in August to a seasonally adjusted annual rate of $793.3 billion. Gains were seen in all three major building sectors: nonresidential building starts rose 16% and residential building climbed 12%, while nonbuilding construction jumped 40% over the month. While large projects certainly influenced the August gains, removing those projects would still have resulted in a gain for the month.

Year-to-date through the first eight months of the year, starts were 14% lower than in the same period in 2019. Nonresidential starts were 24% lower and nonbuilding starts were down 20%, but residential starts were down less than one percent. For the 12 months ending August 2020, total construction starts declined 6% from the 12 months ending August 2019. Nonresidential building starts fell 13% and nonbuilding starts were 9% lower in the 12 months ending August 2020, while residential building starts rose 3%. In August, the Dodge Index rose 19% to 168 (2000=100) from the 141 reading in June. The Dodge Index was down 8% compared to a year earlier and 6% lower than its pre-pandemic level in February.

“Construction starts continue to make up ground following the nadir in activity in April,” stated Richard Branch, Chief Economist for Dodge Data & Analytics. “Residential and commercial construction are driving the gains, while the public side of building construction is proving to be a drag on growth. The regional pattern has also evened out with gains in starts seen in every region but the Midwest in August — somewhat muting the concern over the potential impact of rising COVID cases in the South and West. The nascent recovery in starts, however, will face challenges as summer turns to fall. The expiration of enhanced unemployment insurance benefits and small business loans that were provided in the CARES Act, the budget crises facing state and local governments, and the impending expiration of the FAST Act on September 30 will all have a dampening effect on starts.”

Nonbuilding construction posted a 40% gain in August to a seasonally adjusted annual rate of $184.4 billion nearly reversing the sizable decline in the previous month as two large projects pushed activity higher. Starts in the utility/gas plant more than doubled, while environmental public works posted an 89% gain and highway and bridge starts moved up 13%. Miscellaneous nonbuilding starts lost 5%.

The largest nonbuilding project to break ground in August was the $1.3 billion Wastewater Control Plant in San Francisco CA. Also starting during the month were the $888 million Dania Beach Clean Energy Center in Dania Beach FL and the $310 million new Aztec Stadium at San Diego State University in San Diego CA.

Through the first eight months of the year, total nonbuilding starts were down 20% compared to the same period in 2019. Starts in the highway and bridge category were up 1%, while the environmental public works category dropped 15%, the miscellaneous nonbuilding sector fell 34%, and the electric power/gas plant category plunged 45%. On a 12-month rolling basis, total nonbuilding starts were down 9% in the most recent year compared to the 12 months ending August 2019. Starts in the street and bridge category dipped 2%, while starts in the electric power/gas plant category were down 12%. Environmental public works starts pulled back 8% and miscellaneous public works starts dropped 21%.

Nonresidential building starts in August were also aided by large projects in the office and manufacturing sectors leading to an increase of 16% to $236.7 million. Removing these projects, however, would not have prevented an increase in nonresidential building starts. Commercial starts rose 36% and manufacturing starts soared 201%. Institutional starts, however, fell 7% despite small gains in education and healthcare.

The largest nonresidential building project started in August was the $1.0 billion Facebook Data Center (Project Woolhawk) in Gallatin TN. Also starting during the month was the $740 million Texas Instruments Fabrication Plant in Richardson TX and a $700 million mixed-use office and hotel project in Boston MA.

On a year-to-date basis, total nonresidential building starts were 24% lower than in the first eight months of 2019. Institutional building starts dropped 16%, while commercial starts slid 27% and manufacturing starts were 47% lower than a year earlier. Over the 12 months ending August 2020, total nonresidential building starts were down 13% from the 12 months ending in August 2019. Commercial starts were 16% lower, institutional starts were down 13%, and manufacturing starts slipped 1%.

To read the original online article – CLICK HERE

Issues Impacting Commercial Construction

The construction industry has always been important because of its fundamental role in building society as we know it. However, the industry is facing some critical issues that will be crucial for its future development. Here are some of the most essential issues impacting the commercial construction industry.

Worker Safety

First and foremost, there’s the issue of safety. The construction industry has been struggling with worker safety for years. The commercial construction industry is one of the leaders in the total number of worker deaths. Keeping workers safe has been a major source of concern among employers within the industry.

There are several ways to protect workers from accidents and injuries while they do their job. The most obvious is training. Training employees to become better at protecting themselves in critical situations can prevent them from getting injured and prevent accidents from happening. Training employees to be better specialists, on the other hand, will help them perform their tasks more accurately, precisely, and safely.

Another way to reduce the number of accidents and injuries in the workplace is by getting rid of hazards. All the safety measures for storage, transportation, and use of potentially dangerous objects should be strictly followed to ensure that the risk of disaster is reduced. Continuously training your workers can also help employees better understand what should be done in different situations and what objects should be stored in what conditions.

Technology Use

Another issue that will ultimately impact the commercial construction industry is the adoption of technology. The construction industry is notorious for adopting new technologies very slowly. Many construction business owners tend to underinvest in new technologies despite knowing that these technologies can significantly improve the results and performance of any project.

Emerging technology like virtual and augmented reality, robots, drones, and 3D printing are all examples of such new underused technologies that are being adopted by the construction industry day by day. Hopefully, more projects will be completed with the help of new technologies.

Many issues and problems listed in this article can easily be solved by using a certain technology. For example, drones can be used to improve security and keep employees safe by monitoring everything from above and ensuring that every process is performed correctly. Project management software can help with scheduling and planning while VR and AR can help with visualizing the final product.

Labor Shortage

One thing that not everyone anticipates in the construction industry is the labor shortage. Ever since the Great Recession, the employment numbers in the construction industry have been struggling to get back to their prerecession statistics. Over 2 million jobs were shed by the industry during the economic downturn of the late 2000s with workers either leaving voluntarily or being fired.

These workers mostly found jobs in other industries that sustained them for a while. But what happened next is that many of them realized they were better off in those jobs. Many of these specialists didn’t come back to the construction industry creating this labor shortage. Moreover, the construction industry is not attracting enough talent to meet the growing demand for qualified professionals and specialists.

Employers should be more mindful of the experts they already have employed in their firms. More and more companies are realizing how important it is to create the right offer to “sell” their unoccupied positions to potential candidates. If employers have opportunities to offer that others don’t, they are more likely to get to hire the specialist they are looking for, i.e., skilled, experienced, educated, and motivated.

Decreased Productivity

Decreased productivity seems to be a pain point for many spheres, so it’s obvious that the commercial construction industry suffers from it as well. The problem is that construction projects are becoming more and more complex every year which is why the decreased productivity is way more damaging than it seems. Multiple factors lead to decreased productivity which is why it is so hard to prevent it completely.

For example, improper scheduling and planning are some of the primary causes of decreased productivity. When employers and employees have no idea what they are supposed to do and what aims they should be pursuing, they become increasingly demotivated. That’s where the decreased productivity starts setting in. It’s crucial that the proper amount of time is dedicated to planning and preparation.

The lack of collaboration and communication can lead to a lot of time wasted on insignificant matters which also results in less work completed and, consequently, decreased productivity. In addition to all of that, the shortage of labor can contribute to this issue as fewer specialists can be working on one project at the same time. In other words, there are multiple things you should keep in mind to truly start increasing productivity on a construction project.

To read the original online article at ConstructConnect – CLICK HERE

Building Energy Efficiency

How a decades-old design concept is transforming the energy efficiency of buildings

The buildings we live and work in have to meet a wide range of needs, whether it’s an office block in the middle of the city or a small house in the suburbs.

Think of a building’s temperature: It can be regulated by radiators, fans and air conditioning systems, while basic actions such as opening and closing a window or door can also be effective. Today, smart technology allows many of these appliances to be controlled remotely using smartphones.

You only need to look at your monthly utility bill to know that living in a building — be it large or small — costs money.

The impact of buildings on the environment is also a concern. According to the IEA, final energy use in buildings hit approximately 3,060 million tons of oil equivalent (Mtoe) in 2018, up from 2,820 Mtoe in 2010.

Fossil fuels’ share in buildings’ energy use was at 36% in 2018, the IEA says, a small drop compared to 38% in 2010.

The ‘Passivhaus’ concept

It’s not surprising then, that as people around the world become increasingly conscious about sustainability and the impact human actions have on the environment, one idea that is becoming influential is the Passive House – or Passivhaus – concept.

The world’s first Passive House was built in the city of Darmstadt, Germany in the early 1990s. According to the Passive House Institute, which was established in 1996 and is also based in Darmstadt, the concept is grounded in five principles: superior windows; airtight construction; ventilation with heat recovery; quality insulation; and thermal bridge free design. In order to be certified as a Passive House, a building has to meet a range of detailed, strict, criteria.

Today, the concept continues to influence architects and designers around the world. The 2019 winner of the prestigious Royal Institute of British Architects (RIBA) Stirling Prize — which is awarded to the best new building in the U.K. — was Goldsmith Street, a development of around 100 low-rise homes in the English city of Norwich. According to RIBA, the development “meets rigorous ‘Passivhaus’ environmental standards.”

All of the homes, RIBA says, are south facing in order to “maximise solar gain” while each wall is more than 600 millimeters thick. In addition, subtle efforts have been made to boost insulation: these include mailboxes being installed in external porches rather than doors to tackle draughts.

Other examples of Passive House buildings include schools, office buildings and factories, the Passive House Institute says.

‘Soft’ benefits

Just how important will passive design be in the years ahead, then?

“It is the future of construction – building better,” Giorgia Tzar, associational manager at the International Passive House Association, told CNBC via email.

“Passive House buildings are sustainable not only because they are built to last, but they reduce operational energy — and thus operational emissions — enormously,” Tzar added.

Tzar went on to explain that Passive House buildings offered “soft” or indirect benefits such as lowering the running costs of a building due to low heating and cooling demand.

Indeed, the architecture firm involved in the Goldsmith Street project, Mikhail Riches, says its design was intended to provide residents with fuel bills of around £150 ($191.18) a year.

Karl Desai, from the U.K. Green Building Council (UKGBC), explained to CNBC that another key benefit was the “interaction with the natural environment and ensuring that the building is responsive to what’s happening externally.”

“That … creates a nicer space internally as well,” Desai, who is projects manager for Advancing Net Zero at the UKGBC, added.

To read the original online article – CLICK HERE

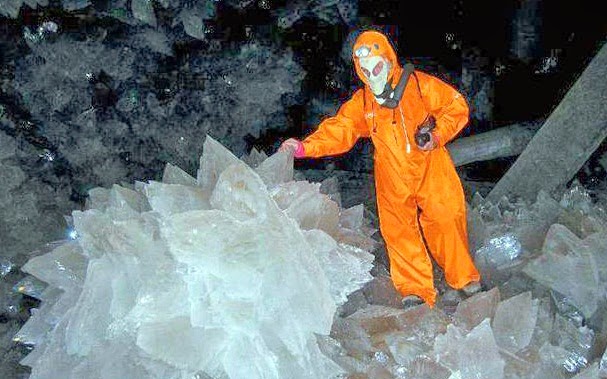

Cave of Crystals “Giant Crystal Cave” at Naica, Mexico is all a form of Gypsum

Discovered by chance, the secret Mexican crystal caves big enough to drive a car through.

The Naica Mine of the Mexican state of Chihuahua, is a working mine that is best known for its extraordinary selenite crystals. Located in Naica in the municipality of Saucillo, the Naica Mine is a lead, zinc and silver mine operated by Industrias Peñoles, Mexico’s largest lead producer. Caverns discovered during mining operations contain crystals of selenite (gypsum) as large as 4 feet (1.2 m) in diameter and 50 feet (15 m) long.

Formation of the gypsum crystals

Naica lies on an ancient fault and there is an underground magma chamber below the cave. The magma heated the ground water and it became saturated with minerals, including large quantities of gypsum. The hollow space of the cave was filled with this mineral-rich hot water and remained filled for about 500,000 years. During this time, the temperature of the water remained very stable at over 50 °C (122 °F). This allowed crystals to form and grow to immense sizes.

How did the gypsum crystals reach such superheroic proportions?

In the new issue of the journal Geology, García-Ruiz reports that for millennia the crystals thrived in the cave’s extremely rare and stable natural environment. Temperatures hovered consistently around a steamy 136 degrees Fahrenheit (58 degrees Celsius), and the cave was filled with mineral-rich water that drove the crystals’ growth.

Modern-day mining operations exposed the natural wonder by pumping water out of the 30-by-90-foot (10-by-30-meter) cave, which was found in 2000 near the town of Delicias. Now García-Ruiz is advising the mining company to preserve the caves.

Exploration and scientific studies

A scientific team coordinated by Paolo Forti, specialist of cave minerals and crystallographer at the University of Bologna (Italy) explored the cave in detail in 2006. To survive and to be able to work in the extreme temperature and humid conditions which prevent prolonged incursion in the crystal chamber, they developed their own refrigerated suits and cold breathing systems (respectively dubbed Tolomea suit and Sinusit respirator).

Special caving overalls were fitted with a mattress of refrigerating tubes placed all over the body and connected to a backpack weighing about 20 kg (44 lbs) containing a reservoir filled with cold water and ice. The cooling provided by melting ice was sufficient to provide about half an hour of autonomy.

Beside mineralogical and crystallographic studies, biogeochemical and microbial characterization of the gypsum giant crystals were also performed. Stein-Erik Lauritzen (University of Bergen, Norway) performed uranium-thorium dating to determine the maximum age of the giant crystals, about 500,000 years.

Penelope Boston (New Mexico Institute of Mining and Technology), speleologist and geomicrobiologist specialist of extremophile organisms realized sterile sampling of gypsum drillcores by making small boreholes inside large crystals under aseptic conditions. The aim was to detect the possible presence of ancient bacteria encapsulated inside fluid and solid inclusions present the calcium sulfate matrix from its formation.

Solid inclusions mainly consist of magnesium and iron oxy-hydroxide but no organic matter could be found associated with the solid hydroxides. No DNA from ancient bacteria could be extracted from the solid inclusions and amplified by PCR.

Microbial studies on fluid inclusions are foreseen to attempt to evidence the presence of ancient micro-organisms in the original fluid solution in which the crystals developed.

Other researches also cover the fields of palynology (pollen study), geochemistry, hydrogeology and the physical conditions prevailing in the Cave of Crystals.

To read the original online article – CLICK HERE

Sustainable materials to reinforce concrete structures

A more sustainable material to reinforce concrete structures of all types from building foundations to high rise towers.

The next generation of ultra high-performance fiber-reinforced concrete (UHPFRC) has just been created at EPFL. The new material will be used to strengthen and to extend the life span of bridges and other structures—both new and old. What’s more, the process of manufacturing this material releases 60–70 percent less CO2 than the previous generation of fiber-reinforced concrete.

The construction industry accounts for around 40 percent of global CO2 emissions, much of which can be attributed to the manufacture of concrete. And countries like Switzerland, where concrete structures have flourished since the 1960s, now face the task of maintaining these structures to ensure they remain safe far into the future. This is a daunting challenge with both environmental and technical considerations.

EPFL’s Structural Maintenance and Safety Laboratory (MCS), headed by Eugen Brühwiler, has built up cutting-edge expertise in this field over the past 25 years. The MCS specializes in two areas: developing more ecofriendly concrete, and carrying out increasingly sophisticated, largely monitoring-based, assessments of existing structures, such as road and rail bridges in Switzerland and around the world.

For his Ph.D. thesis, MCS researcher Amir Hajiesmaeili sought to develop the next generation of ultra high-performance fiber-reinforced concrete (UHPFRC). His aim was to develop a material that retains the mechanical properties found in today’s concrete, but without the steel fibers. The UHPFRC that Hajiesmaeili came up with is 10 percent lighter than other fiber-reinforced concrete, and its environmental impact is 60–70 percent lower. This new material is so effective that the first tech transfer will take place in 2020, when it will be used to reinforce a bridge.

Right recipe

Hajiesmaeili likes food and knows his way around a kitchen. After completing a Master’s degree in civil engineering at the University of Tehran, he came to EPFL to do his Ph.D. as part of the Swiss National Science Foundation’s NRP “Energy Turnaround” (NRP 70) project. He spent nearly four years “cooking” at EPFL. Each week he would prepare various combinations of powders in a scientific way, according to a novel comprehensive packing model that they developed in MCS and stir them up in a mixer. He would then run his samples through various strength and tensile tests and refine his calculations. His aim was to produce a new UHPFRC that is just as strong as the one currently used in the construction industry but that produces less CO2.

“After three years of this trial-and-error, we finally found the right recipe—one that also meets stringent building standards,” says Hajiesmaeili. How did he do it? Instead of steel fiber, he used a very stiff synthetic polyethylene fiber that adheres well to the cement matrix. He also replaced half of the cement, a commonly used binder in concrete, with limestone, a material that is widely available around the world. “The trick was to find a material that’s very strong and produces the right consistency.”

Swiss technology

For the past 15 years, first-generation UHPFRC has been used to reinforce bridges to make them more sustainable, thanks to a technology developed in Switzerland and exported abroad. Its carbon footprint is already lower than that of conventional reinforced concrete. “With this material, we can add value to age-old structures by ensuring they will last for a long, long time,” says Brühwiler, whose lab has already overseen the structural reinforcement of more than 100 bridges and buildings in Switzerland. “This solution is also much more financially and environmentally sound than razing and rebuilding existing structures like bridges and historical monuments.”

In Brühwiler’s experience, technology transfer in the construction industry is only effective when three criteria are met: people at every step of the construction chain—from construction managers to workers—are well-trained (as is the case in Switzerland); there is a building code; and there are both financial and individual incentives for stakeholders to change their habits.

To read the original online article – CLICK HERE

Women in Construction

Women construction leaders discuss building their careers, demolishing glass ceilings.

At the beginning of her career, civil engineer Rebecca Clark tried to stay under the radar and assimilate with her peers — almost all of them men. For many years she thought it was important to not stand out in the workplace.

As she rose in her career and saw more women entering the construction field, she began to embrace her unique skill set.

Clark, now an operations executive at Skanska, was part of a panel at the sold-out Women in Construction Leadership and Networking Conference here on Oct. 19. She and three other women panelists told the audience of 450 that in a male-dominated field like construction, female employees’ skills and talents are invaluable.

These strengths include perceptiveness, organizational and listening skills, empathy and a willingness to collaborate, speakers said.

“Maybe it means you can read somebody’s body language in a meeting or the scowl on their face to know how to pivot the conversation and redirect the discussion to your advantage,” said moderator Clare Archer, vice president at Gilbane Building Co.

Females’ unique set of traits dovetail with those of men in the office and on the jobsite, panelists said. “What I’ve learned over the years from working in this field is that men and women are different and that’s OK,” Archer said.

Brailsford & Dunlavey Senior Project Manager Sarah Pearlstein agreed, telling attendees that when it comes to construction projects, “there’s more than one way to skin a cat. Some people go from A to B to C and some go from A to Z back to B and C,” she said. “Both of those types of people get to C in their own way.”

Panelists provided an array of advice to women in the industry, including:

- Women should not be afraid to stand out at work, Pearlstein said. “Build your personal brand, get involved and make sure you find things that you care about, whether it’s your local Women in Construction chapter or whatever that passion looks like for you,” she said. “Get involved so that it’s not just people in your company but people in the industry recognize you.”

- Clark echoed that sentiment, saying female workers should champion things they are passionate about such as community involvement, mentoring younger workers, or driving change in the workplace. “Even if it’s for something that’s going against the tide, you will stand out if you’re passionate about whatever initiatives you’re behind.”

- Archer recommended the book “How Women Rise: Break the 12 Habits Holding You Back from Your Next Raise, Promotion, or Job” by Sally Helgesen as a resource to help identify and overcome issues that slow women’s career success.

- Women in construction have to be thick-skinned and willing to claim their achievements, Archer said, urging audience members not to diminish their worth. “Sometimes we minimize with our words, such as “this will just take a minute’ or ‘I just need you for this one quick thing,’” she said. “This gives the impression that your opinion isn’t valuable enough for anyone to spend time listening to.”

- Female managers should try not to take it personally if coworkers disagree with a decision. “It’s just not possible to always make everybody happy,” Pearlstein said. “Don’t feel like if people aren’t pleased with the way you’re moving forward that you made the wrong decision.”

- Additionally, if a woman makes a mistake, she should avoid dwelling on it, said panelist Amy Mercurio, senior director of design and construction for Johns Hopkins Facilities & Real Estate. “I’m constantly Monday morning quarterbacking,” she said. “It’s better to accept what you did and know you’ll do better next time.”

- A common habit of female employees, sharing personal information, sometimes puts women in a negative light, Archer said. “Women share their faults and problems as a way to bond with one another,” she said. “Men don’t do that, and for the most part they set workplace cultural standards around the world so routine personal disclosures about your doubts and weaknesses are more likely to diminish your credibility than to help it.”

- All panelists mentioned the importance of developing mentors, both men and women and both in and out of the construction industry. “Find a safe space of coworkers that you can trust,” Clark said. “There’s a lot of power in that.”

- Pearlstein noted that making time for working with a mentor is important but sometimes difficult. “Those types of relationships require some work, because the person might not be three doors down the hallway from you,” she said. “Go to lunch, grab coffee, make those long-lasting relationships. They’ll really go a long way.”

To read the original online article – CLICK HERE

Wood vs Concrete, a Material Perspective

Wood vs Concrete, a Material Perspective: Cement Association of Canada

This is an excerpt from an article found in Building Magazine about the difference between Concrete or Wood with construction. The good news is that there’s an AccuCrete® product that will work regardless of the base product!

Interview with: Adam Auer, Vice President, Environment and Sustainability and Richard J. McGrath, Director Codes and Standards – Buildings

Overview on Concrete high-rise construction in Canada

Concrete is often seen as an “old” if proven technology for residential and commercial construction over six stories. How has it evolved over the last decade in the digital age and the application of new technologies? What changes are taking place or will take place in the near future that will keep concrete in the forefront?

Richard McGrath: [Before we started] you mentioned the use of maturity embedded sensors in poured concrete. That is just one of the technologies being applied today more and more in the construction of our larger and more demanding concrete projects to reduce both labor and construction schedules. One of the biggest innovations that I have personally been involved with over the last decade is the introduction of Portland Limestone cement by the Canadian concrete industry. This reduces our emissions from both the fuels used in the manufacture of the cement and in the calcination reaction process in the limestone itself. We are reducing greenhouse gas emissions by 10 per cent with the manufacture and the use of Portland Limestone cement.

Nothing gets into the marketplace or into the industry until it’s approved by relevant standards. And we have just recently standardized ultra-high performance concrete manufacturing in Canada. We expect to see more use of ultra-high performance concrete that is incredibly durable and allows us to construct concrete structures in the most aggressive environments while providing the longest service life possible. This is certainly an advancement that has gone from being an ultra-specialized product to now being more mainstream.

We are also improving with every code cycle the economics of our concrete mix designs by recognizing finer grading of aggregates, which reduces the demand for cement in concrete mixes. This improves environmental sustainability while providing the same quality concrete. We are also adapting to the use of higher strength reinforcement for reinforced concrete that allows us to improve the constructability of these buildings and to utilize more economical concrete designs for our most demanding design projects.

We were talking about prefabrication as being an innovation in the construction industry. Yes, in the future many more projects because of the constricted sites in highly dense urban areas will require more prefabrication than on-site construction. But this competency has been practiced in precast concrete construction and prefabrication for decades in Canada. This technology is reaching new heights as you have pointed out with the [27-story] Marriott Hotel in New York. And we also have on-site, precast tilt up construction that is being used extensively on both the east and west coasts of Canada.

We saw just recently the emergence of 3D concrete printing for residential housing in some applications. And although this isn’t currently recognized in our codes in North America, in the coming [code] cycles I would expect that they will recognize this new technology as well. There is also self-healing concrete. These are rich cement content mixes that are demonstrating some self-healing capabilities after cracks form. These cracks can heal themselves because of the additional cement in these mixes. It hydrates with any ingress of water and serves to seal the concrete.

In each code cycle there is developing an increased flexibility in our design capability for our structures. You are now seeing structures with inclined columns and spiralling facades of a more complex architectural nature. These never would have been possible years ago if not for the advancement in the computerized design techniques for concrete structures and in the capability of concrete to accommodate these increased design demands.

These are just a few of the advances in concrete technology that we have seen utilized in the industry and there are more to come no doubt.

The Wood vs Concrete debate: Cost of building tall.

How does concrete compare with tall wood structures in terms of project cost from a) start to occupancy as well as b) total life cycle cost? Have you looked at it in terms of what is the cost implications between concrete and wood for taller buildings?

First I would point out that many, if not all of the recent tall buildings are really not all-wood structures. There is a fair degree of concrete construction [in these buildings] to handle the heavy lifting. Anywhere you have a concentration of loads or high stress levels, invariably you will see steel connections or concrete employed to take these high stresses and high loads. So it’s relatively easy from an engineering point of view to hang a gravity-loaded frame off of these concrete cores such as you see in Brock Commons [at UBC] as just one example. All of the heavy lifting is done with the foundations and the podium level providing a solid base for the structure and all the lateral loads due to wind and earthquake are being resisted by the concrete cores. Now, you simply secure the wood framing back to the concrete core and let it support gravity loads only, removing any need for moment-resisting connections or torsional resistance. In other words, concrete is counted on to do the heavy lifting while the wood frame goes along for the ride.

That is the first thing. You are never going to see an all-wood, 12-story building in Canada, not from this next code cycle. The limitations that are recognized for tall wood buildings will limit solutions to six-stories in our high seismic zone if you want an all-wood building [including the core]. So your [all] CLT wood building will only be six stories in high seismic zones and no higher than ten-stories in the rest of Canada. For fire safety purposes, the code will permit 12-stories, but they will all be hybrid structures where you’ll see concrete elevator cores, stairwells, and podiums supporting the gravity frame wood in these structures. Any all-wood building design greater than 10 stories will fall outside the scope of the 2020 NBCC and will have to be approved as an alternative solution by the authority having jurisdiction.

Adam Auer. I think that in terms of cost it is difficult to say since most of the taller wood buildings, six stories and up, have been underwritten at least in part through federal and provincial subsidies. So there aren’t enough of them yet to determine what the cost comparison will be at the end of the day. But it certainly seems at the moment that these buildings cannot be built unless they have at least some support from government funding.

Richard: That is an interesting fact. When the proposals were being made at the National Building Code level, the proponents failed to recognize that all of these projects demonstrating the capability of the material had been subsidized projects and there was no cost savings. In fact, in many instances there were cost premiums being paid to build these structures. They never would have gone ahead had it not been for the subsidies provided.

Are you aware of the Japanese architect Ban’s proposed 17-story condominium tower in Vancouver? It will have 2-storeys above ground podium and a core in concrete and the top 15 stories will be wood with exposed mass timber framing on the top six stories. It also uses concrete curtain wall panels on the first six stories hung on the wood frame.

Richard: That’s an interesting observation. As you see in most of these structures concrete is used for not only the foundations but the first couple of floors. That gets the wood component of the structure up and out of the high exposure area and the damage prone zone, not only from the environment but from impacts around the structure or damage by fire . It just improves the durability of the structure by getting the most vulnerable component up and out of the way of the high hazard areas.

One of the issues raised around wood structures is that it requires higher maintenance than concrete in areas associated with material deterioration from water, rot, insects, etc. Do you see these as valid concerns that haven’t been fully resolved?

In the latest code cycle – I’ve been at it for 37 years with the association – everybody was talking about the speed of construction and how much cheaper it was going to be. Nobody was talking about improving the building envelope on these structures to make sure that you didn’t have any moisture ingress. It is very interesting that many of our first high-rise wood projects are being built in British Columbia, which as you know is a jurisdiction that suffered from some of our worst serviceability construction losses in Canadian history. As a condo developer, I would find it very difficult to rush to adopt this line of construction in this perilous region of the country in regards to wood frame construction.

The argument is made that one advantage to wood is it takes less time to construct a wood structure. While this may be so onsite, how does the timeline look when the off-site fabrication of components is added? Alternatively, Marriott Hotels has started construction on a 27-story hotel in New York using prefabricated concrete modules that will go into place completely finished in 90 days (not including foundation and two story podium). Can/is concrete module technology thus already competing with wood in this area?

You are exactly right. There is greater emphasis being placed on this form of construction as constriction increases for on-site construction. One of the advantageous attributes of concrete construction is that you can modularize the construction process so effectively. I could look back to Habitat 67 in Canada and all the design innovations that it brought to the world stage. Habitat 67 was one of the first attempts of modularized residential construction here in Canada. While it didn’t take off at that time, its time may have come, and if projections are accurate, more structures will be built in the future using this design concept.

The Marriott hotel is a more recent example, but the beauty of this form of concrete construction is that these living units can be constructed and assembled in climate controlled factory conditions with all of the services built in. All of the services and finishes are embedded in the concrete. Concrete construction, as you know, facilitates embedment of services within the structural frame protecting it from all elemental deterioration as well as providing a long service life. So the short answer to your question is “Yes.” This is a coming trend recognized by more than our industry and we will see more of it. The concrete industry will continue to evolve and accommodate more and more of these types of building construction practices.

To read the original online article – CLICK HERE